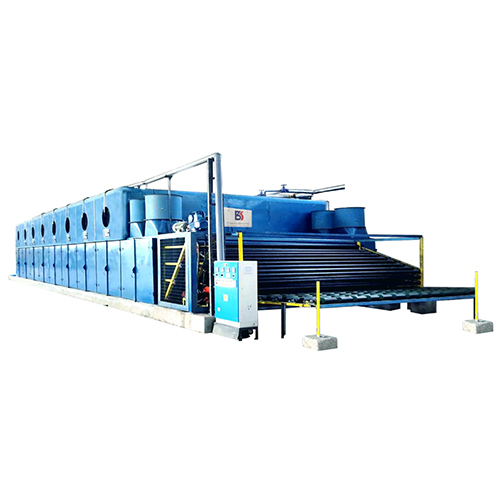

Roller Veneer Dryer

500000 INR/Piece

Product Details:

X

Roller Veneer Dryer Price And Quantity

- 1 Piece

- 500000 INR/Piece

Product Description

| DRYER MODEL | Dryer Length Ft | Roller Size Length OD | Drying Capacity in 24 Hrs. for 1.8mm Thick Green Veneer Thermic Fluid Steam Sqft CBM Sqf Power HP S | Power HP STD ADV | Requirement of Thermic Steam Kcal/Hr Kg/Hr |

|

| 6 Section 4 Deck | 56 | 4600 114 | 225000 38 190000 | 38 52 | 700000 1.5 Ton | |

| 8 Section 4 Deck | 80 | 4600 114 | 330000 55 280000 | 50 67 | 1000000 2.5 Ton | |

| 10 Section 4 Deck | 97 | 4600 114 | 420000 70 380000 | 65 85 | 1200000 3.0 Ton | |

| 12 Section 4 Deck | 130 | 4600 114 | 500000 80 450000 | 78 96 | 1400000 3.5 Ton | |

| High Efficiency Dryer with Auto Feeder 12 Section 4 Deck | 120 | 4600 114 | 600000 100 Not Suggested | 140 |

|

5.8 M Wide Veneer Dryer also available. Input Moisture: 40 percent to 50 percent Output Moisture 6percent to 8 percent

| Features | Advantages |

| Auto Removal of Humidity | Remove Excess Humidity to maintain required Humidity Level for proper Quality Drying. Stops Loss of Hot Air and Increase Productivity by 8 10 Percent |

| Auto Speed Control of Dryer Conveyors based on temperature Variations | Incresaes Overall Productivity Per Day in 24 Hours running period with standard Drying & avoid Over Under Drying of Veneer. |

| Production and Energy Data Log | PLC & HMI based Monitoring system helps Management to Monitor Overall Performance and Down Time. |

| Individual Dryer Conveyor Deck Speed Control | Can Control Speed for Full Core Veneer and Fail Core Veneer Feeding. |

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free