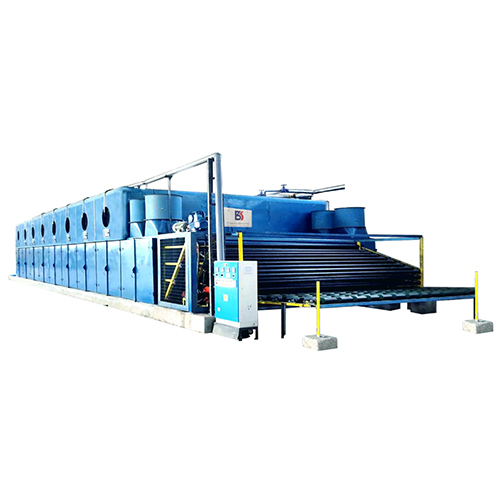

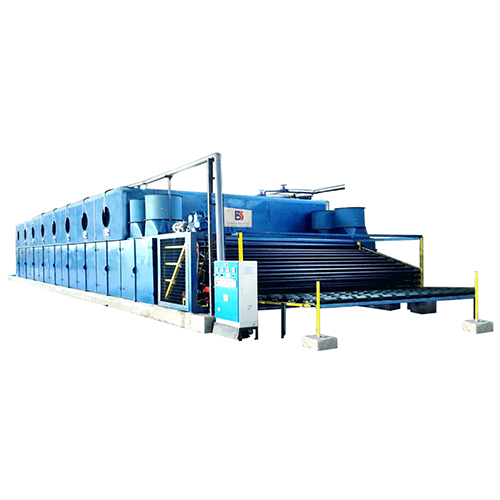

Advance Roller Veneer Dryer with Auto Feeder

Advance Roller Veneer Dryer with Auto Feeder Specification

- Frequency

- 50-60 Hertz (HZ)

- Voltage

- 110-215 Volt (v)

- Features

- Good Quality

- Control System

- Semi-Automatic

- Power Source

- Electricity

- Operating Type

- Semi Automatic

- Surface Treatment

- Coated

- Color

- Blue

- Warranty

- 1 year

- Usage & Applications

- Industrial

Advance Roller Veneer Dryer with Auto Feeder Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 10-15 Days

About Advance Roller Veneer Dryer with Auto Feeder

This is Semi Automatic Veneer Feeder for Dryer. The Veneer palletstobe Placed by Fork Lift to 2 Nos. Scissor lifts at Auto Feeder end. Once the veneer pallets Placed on Scissor Lift 3 no worker can start Veneer feeding. Once the toppressing roller is pressured down on the feeding roller by pneumatic cylinder the Automatic Veneer Feeder Unit puts the veneers in respective decks. The Veneer Feeder unit moves up and down by help of Hydraulic Cylinders stops at desired levels by the help of Sensors / encoders PLC HMI of the Decks. Power requirement 2 Hp for Feeder 15 Hp for Hydraulic Station and 2 Nos. Scissor Lifts. Suitable for Veneer thickness 1 4mm. Machine Length 4600mm, Width 1200mm Height 1490mm

| Technical Data: | Material of Construction |

| Steel Roller 2 No. | OD 216mm 4655mm Heavy Steel Roller |

| Snubber Rollers 2 No. | 195mm 4600mm Synthetic High-Density Rubber |

| Feeder Roller Power | 2.0 H.P. For Feeder Roller |

| Hydraulic Station Power | Very Heavy-Duty Power-Pack of 15 H.P. For Pump for Synchronized Operation of Scissor Lift & Feeder Unit Cylinder Piston Movement |

| Control Panel | PLC HMI based supported by Sensors / Encoders etc |

| Dimensions of Machine | Width 1200 mm Height 1490 mm Length 5800. |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Veneer Drying Machine Category

Roller Veneer Dryer

Price 500000 INR / Piece

Minimum Order Quantity : 1 Piece

Country Of Origin : India

Power Source : Electricity

Control System : SemiAutomatic

Surface Treatment : Coated

Roller Veneer Dryer

Price 500000 INR / Piece

Minimum Order Quantity : 1 Piece

Country Of Origin : India

Power Source : Electricity

Control System : SemiAutomatic

Surface Treatment : Coated

Mesh Band Dryer

Price 500000 INR / Piece

Minimum Order Quantity : 1 Piece

Country Of Origin : India

Power Source : Electricity

Control System : SemiAutomatic

Surface Treatment : Coated

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free